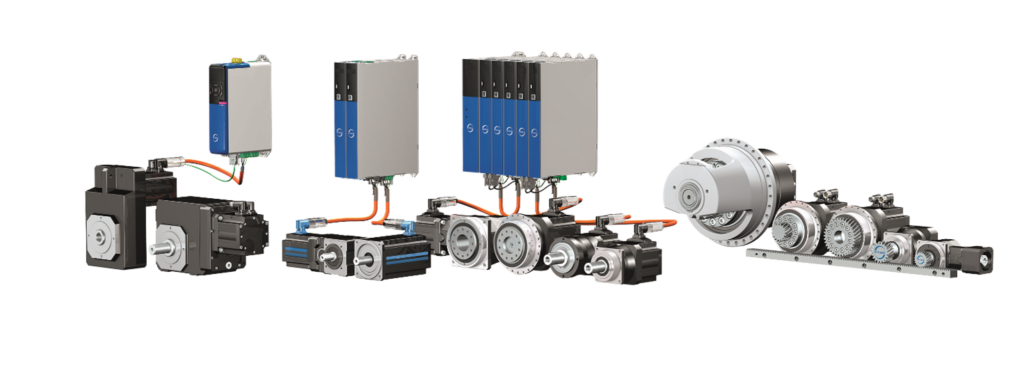

SC6 two-axis servo drives

Stober servo drive, motion controller max. two electric synchronous motors with permanent magnets or asynchronous. Integrated ProfiNET / EtherCAT communication. Output currents from 4.5 to 19A at 4kHz. Positioning precision up to 37 bits/1 rev. Cooperation with absolute and incremental encoders and resolvers. Built-in power supply. DC coupling of intermediate stages – one braking resistor for multi-axis applications. Free software.

SC6 two-axis servo drives

- Enables extremely cost-effective system design thanks to its integrated power supply and slim design.

- To be combined with the innovative STÖBER lean motor – for example in energy-saving transport systems.

- Used in combination with asynchronous or synchronous motors, servo motors (e.g. EZ/LM series).

Control of Dual-Axis Servo Drives SC6:

- Speed control

- Torque control

- Position control (block positioning and command-based positioning)

- Drive synchronization in MASTER-SLAVE mode

Compatible Encoders for SC6 Dual-Axis Servo Drives:

- Absolute encoders: EnDat 2.1/2.2/3.0 digital (Multiturn/Singleturn), SSI, DSL

- Incremental encoders: HTL/TTL

- Resolvers

Integrated Communication in SC6 Dual-Axis Servo Drives:

- EtherCAT

- ProfiNET

For connection with SIEMENS controllers, we recommend using PROFINET IO in combination with the STOBER Drive Based application. SC6 supports ProfiNET IO-RT communication.

Alternatively, EtherCAT® communication can be used with a CiA 402 interface application.

Configuration and Commissioning of SC6 Dual-Axis Servo Drives:

- Free configuration software: DriveControlSuite

- Includes all functions for efficient use of servo drives in single-axis and multi-axis applications

- The software guides users step by step through the configuration and parameterization process using wizards

- Integrated positioning and drive synchronization functions compliant with plcopen commands

CE Compliance of SC6 Dual-Axis Servo Drives:

- Conforms to relevant EMC directives and meets low voltage and machinery directive criteria

- Built-in EMC filter and high-quality galvanized steel housing

- All servo drives are CE marked

Katalogi

442711_en_11_KAT_Antriebe_und_Automation.pdf – Catalog of Stober drives and controls in English

443272_08_HB_SC6_pl.pdf– Instruction manual for Stober SC6 servo drives in Polish

Safety Functions in SC6 Dual-Axis Servo Drives:

- Implementable safety functions and stop categories according to EN ISO 61800-5-2 and EN ISO 13849-1

- Safe Torque Off (STO)

- STO shutdown time: less than 60 ms

- Stop Category – Stop Category 0

- Safe Stop 1 (with delay) – Safe Stop 1 (SS1-t)

- Stop Category – Stop Category 1

- Certified according to DIN EN 61800-5-2 and DIN EN ISO 13849-1

- Safety Integrity Level (SIL): 3

- Performance Level (PL): e

- Category: 4

- Compliance with the standard requirements is ensured by an external testing institute as part of the EU-type examination