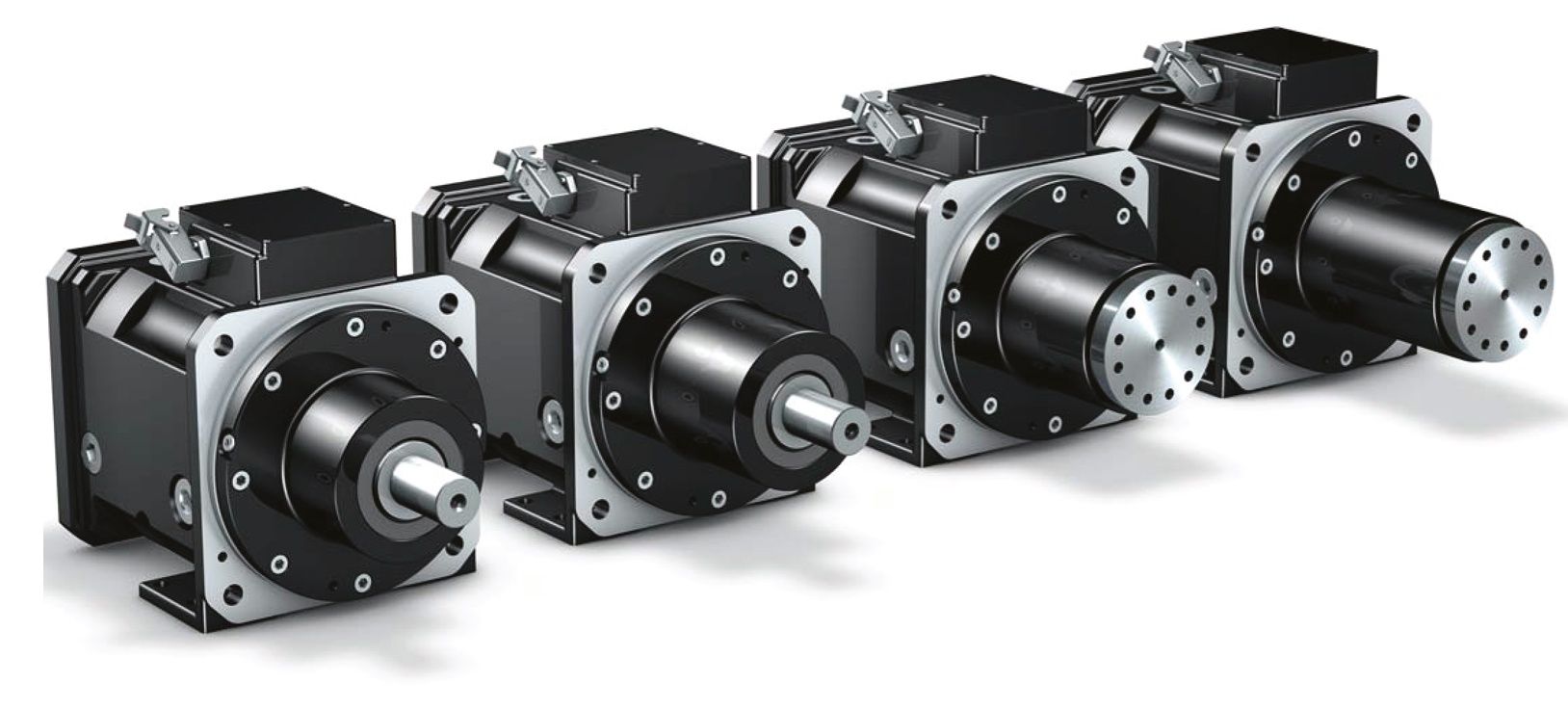

2-speed planetary gearboxes with adapter

2-speed planetary gearboxes with adapter

- PS gearboxes are ideal for all machine tools requiring sophisticated main feed drive concepts: gantry machines, vertical and horizontal lathes or milling and drilling centers.

- Two size groups PS25, PS30

- Extremely energy efficient

- With a double gear ratio of 4:1 (5.5:1) and 1:1, ideal for main spindle drives.

- Quick gear changes between high speeds for fine machining and high torque for heavy machining.

- The transmission temperature also remains constantly low, even with frequent gear changes or maximum engine load.

- Two-speed gearbox with integrated gear changing actuator

- Switching unit with SensorShift function

- The position of the actuator is detected by SensorShift (electronic sensor).

- Choice of standard or reduced rotational clearance

- Maximum permissible gear temperature (on gear surface) ≤ 80 °C

- Protection class IP65

- Easy and safe motor adaptation thanks to the backlash-free clamping coupling

Maximum speeds of two-speed PS gears:

- with circulating lubrication system

- with splash lubrication in S version (angular contact ball bearing)

- with splash lubrication in version R (deep groove ball bearing) or Z (cylindrical roller bearing)

Optional versions of PS two-speed gearboxes:

- circulating lubrication with an external tank

- oil level sight glass or oil level indicator

- circulating lubrication for extremely high speeds

Switching unit with SensorShift PCB for two-speed gearbox:

- SensorShift is an innovative, high-resolution magnetic sensor that precisely records the position of the selector teeth as they engage during gear changes, which momentarily reduces speed to ensure smooth engagement.

- If for some reason the gear teeth do not engage smoothly, the SensorShift mechanism recognizes this and the shifting motor performs a short “reverse motion” to correct the problem. If the switching error level drops below 0.01%, the procedure is repeated, several times if necessary.

- It is connected to the machine control system via a built-in connector.

- The owner’s manual contains notes regarding the switching logic that must be programmed for shifting gears.

- The position of the actuator is determined by an electronic sensor.

- The actuator control system integrated in the switching unit analyzes the position signals and precisely actuates the switching motor.

- Rated voltage 24 V DC −10%, +20%

- Rated current when shifting gears 0.6 A

- Starting current when changing gears 5 A

- Maximum current of contacts S1 – S3 2 A (use a 2 A fuse (slow-blow) as fuse protection)

- Expected service life S1 – S3 500,000 switching cycles (30 V DC, 1 A resistive load)

- Low level digital inputs 0 – 8 V DC

- High level digital inputs 12 – 30 V DC

- Input current for digital inputs < 10 mA

- Reflection time for digital inputs 100 ms

- Shock resistance 20 g (10 Hz ≤ f ≤ 500 Hz)

Advantages of the switching unit with SensorShift:

- There is no need for a customer-side relay or wiring in the control cabinet

- Low complexity of programming the gear shifting process

- The gear shifting process is not time sensitive for the machine control system and can run in the background

- Automatic repetition of the shifting process in case of a shifting error

- Wear-free, non-contact position detection

- The integrated soft start system protects the mechanical parts

- Possibility to shift to neutral from any gear

- The SensorShift PCB version has compatible connections with the previous microswitch design.

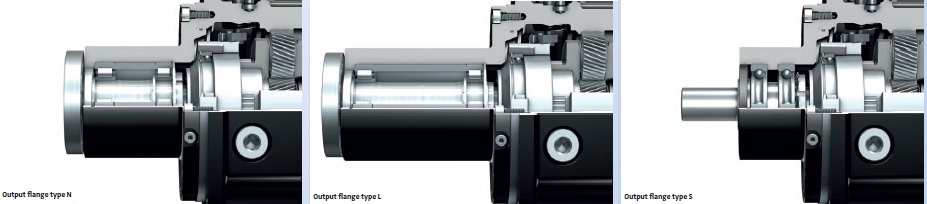

Structures of the output shaft of the PS two-speed gearbox

- Shaft design G (solid shaft without keyway)

- P shaft design (solid shaft with two keyways)

- F shaft design (flange shaft)

Bearings of the output shaft of the 2-speed PS gear:

- Standard (deep groove ball bearing)

- Axially reinforced (angular contact ball bearing)

- Radially reinforced bearing (cylindrical roller bearing)

442712_en_08_KAT_Zweigang-Schaltgetriebe_PS.pdf – Catalog of two-speed PS planetary gearboxes from Stober in English

442639_en_12_BAL_Zweigang-Schaltgetriebe_PS.pdf – User manual for Stober two-speed PS shift gears in English