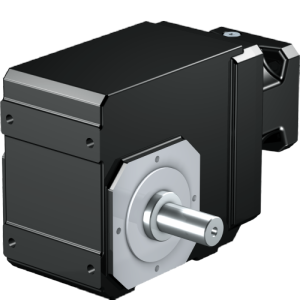

K-ME angular bevel gearboxes

Angular bevel gear unit K with ME adapter for servo motor. Total gear ratio range: 4 – 381. Acceleration torque: 22 – 13 200 Nm. Nominal torque: 15 – 12 000 Nm. Continuous Input Speed: Up to 4 000 RPM. Cyclic Input Speed: Up to 7 000 RPM. Torsional Stiffness: Up to 725 Nm/arcmin. Standard or reduced backlash 1.5 – 12 arc minutes. Efficiency 94 – 97 %. Protection class IP65 / IP66. Optionally with brake, servo motor, rack and pinion or ATEX explosion-proof design. Cast iron housing.

K-ME angular bevel gearboxes

Properties of K-ME bevel gearboxes

- Standard or reduced backlash.

- Precise – gear ratio in the form of a fraction, no positioning errors.

- Maintenance-free – no oil change or maintenance required.

- Quiet – helical toothed gears.

- Standard FKM seal at the input / NBR at the output.

- Small moments of inertia.

- Continuous operation without additional cooling.

- Ambient temperature from 0° C to 40° C (other temperature range on request).

- Max. gear housing temperature ≤ 80 °C.

- Protection class IP65.

- Amount of oil depending on the working position.

- Working position to be specified when ordering.

- Ready for operation and filled with synthetic gear oil type CLP HC ISO VG 150.

- One coat of primer in RAL7001 or RA9005.

Optional versions of the K-ME bevel gear unit

- Reduced rotational clearance.

- FKM Viton seal.

- Protection class IP66.

- Oil reservoir for mounting position EL5.

- Two or more paints and in any RAL colour.

- Special oils for the food industry.

- Explosion-proof design according to ATEX Directive 2014/34/EU.

- Reinforced axial and radial bearing of the output shaft for sizes K5-K8.

- Directly mounted EZ/LM servo motor without adapter and clutch.

- Emergency brake in the servo motor adapter.

- With modular gear wheel and toothed rack.

Output shafts of K-ME bevel gears

- G – full smooth shaft,

- V – full shaft with key,

- V2 – full shaft with key on both sides of the gear,

- A – hollow shaft with keyway,

- S – hollow smooth shaft with clamping ring and cover.

Mounting of K-ME bevel gears

- G – threaded holes,

- N – feet,

- F – round flange,

- D – torque arm.

Applications of K-ME bevel gears

- packing and dosing machines,

- automatic feeders,

- linear Cartesian robots,

- winders, rewinders,

- storage systems,

- robotics,

- cartoning machines.

Features of the K-ME bevel gear motor adapters

- Quick and easy attachment of any servo motor.

- One-piece, robust clamping clutch with expansion function.

- Low mass moments of inertia for highest operating dynamics.

- Balanced for quiet, vibration-free operation, even at high speeds.

- A wide range of motor shaft diameters and lengths.

- A perfect fit thanks to precise motor centring.

- The motor can be removed in any position.

- Optionally double adapter seal for large gear models.

- Optionally without adapter and clutch – direct mounting of the EZ or LM servo motor.

- To reduce the backlash, the motor shaft bearing must have an axially play-free design.

EasyAdapt (ME/MEL)

- One-piece, robust clamping clutch with expansion function.

FlexiAdapt (MF):

- A robust, laser-welded bellows coupling with expansion function.

- With integrated thermal length compensation, compensates for linear expansion of the motor shaft.

- Motor shaft decoupled from axial forces.

ServoStop servo motor adapter with safety brake (MB)

Catalogues

443054_en_05_KAT_Servogetriebe.pdf – Stober gearboxes catalog.

Formularz_przekladnie_STOBER_26082024.pdf – Stober gearbox inquiry form.