Electrical Synchronization in Stöber Servo Drives

Servo Drive Synchronization

Electrical Synchronization of Drive Shafts

The new series of Stöber servo drives includes the SD6, SC6, and SI6 models. The SD6 features a modular design that allows for the installation of optional communication and I/O cards. Industrial communication options include Profinet, EtherCAT, and CAN. I/O cards available are the basic IO6, expanded Xi6, and the Ri6 for resolver handling. This servo drive allows for the control of a single connected motor and is available in a basic safety STO variant or an expanded variant with additional safety functions. The series supports CIA402 applications as well as Stöber’s proprietary Drivebased application.

Newer drive types in a dual-axis configuration include the SI6 and SC6 models. The SI6 requires an external power supply (rectifier) PS6, while the SC6 has a built-in power supply. Both types feature a compact design and built-in communication capabilities via Profinet and EtherCAT. Changing the communication protocol is possible but requires firmware modification. Each drive has 8 digital inputs and motor brake control. Several safety function variants are available, including STO via terminals, Profisafe, and FSoE (Safety over EtherCAT). The newer models support Profidrive, CIA402, and Stöber’s Drivebased application.

Synchronization Function in Stöber Servo Drives

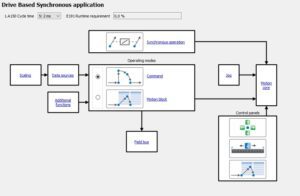

In this section, we will discuss the synchronization application available in the servo drives mentioned above. Configuration is done via the free DS6 – Drive Control Suite application. The discussed application consists of three operating modes: command-based positioning, motion block positioning, and velocity/torque control.

Synchronization refers to the speed coupling of two or more axes. One axis – the master – sends information to the other axis – the slave. Synchronization is possible when the Drivebased – synchronous mode is selected. Synchronization occurs after defining the master and slave axes in the application and initiating the MC_GearIn command. This command complies with the PLCopen standard. Synchronization can also occur with a virtual master across all series 6 servo drives.

The SD6 allows for synchronization through the IGB communication bus for up to 32 axes. Additionally, synchronization can be achieved using an appropriate expansion card with an external encoder, such as SSI.

Both SC6 and SI6 allow the connection of an HTL encoder and synchronization with this encoder. Synchronization is also possible in a dual-axis configuration between axes A and B. Synchronizing more than two axes must be done via a PLC controller.

Advantages of Choosing the Synchronization Application in Stöber Servo Drives

One of the main benefits of using the synchronization application in Stöber servo drives is the savings on PLC licenses, as the activation is carried out using PLCopen function blocks within the servo drive. Depending on the selected servo drive, synchronization can be performed with two or more axes without the need for a PLC, thanks to the motion block application. The synchronization is precise due to the high-quality gearboxes used in the drives. The DS6 application is free, provides an intuitive interface, and includes help and a Polish-language user manual. Furthermore, Demero offers extensive support for selecting the appropriate components, training for operation and programming, and provides example applications.