Command-Based Positioning in Stöber Servo Drives

Command-Based Positioning via Communication

The new generation of Stöber servo drives includes the SD6, SC6, and SI6 models. The SD6 is characterized by its modular design, allowing for the installation of optional communication and I/O cards. Industrial communication options include Profinet, EtherCAT, and CAN. The I/O card can be the basic IO6, the extended Xi6, or the Ri6 for resolver support. This servo drive supports control of a single connected motor. It is available in the basic STO safety version or an extended version with more safety functions. The new generation supports CIA402 applications and Stöber’s proprietary Drivebased application.

The newer dual-axis variants are the SI6 and SC6. The SI6 requires a power supply unit (rectifier) PS6, whereas the SC6 has an integrated power supply. Both types are compact. Built-in communication includes Profinet and EtherCAT. Changing the current communication protocol is possible, but must be done independently by updating the firmware. Each drive has 8 digital inputs and includes motor brake control. Multiple safety function variants are available for STO via terminals, Profisafe, and FSoE (Safety over EtherCAT). These newer models support Profidrive and CIA402 applications as well as the proprietary Drivebased application from Stöber.

Drivebased Application in Stöber Servo Drives

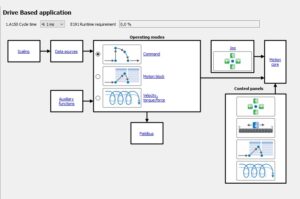

Let’s take a closer look at Stöber’s Drivebased application, which is available in the above-mentioned servo drives. Parameterization is carried out in the free DS6 software – Drive Control Suite. The application includes three operation modes: command-based positioning, motion block positioning, and velocity/torque control. Below we focus on the command-based positioning mode.

This application allows selection of control and status words during the network communication variable mapping process. All basic words are already mapped in the application, but users can edit the list. Control words related to the drive and positioning commands are available. Additionally, changes in drive state are monitored (e.g., enabling the signal or error reset). It’s also possible to read the current status and any error codes.

To trigger a positioning command, a specific value must be sent to word J40 (e.g., sending 1 activates the MC_MoveAbsolute command, which is absolute positioning). Other essential values include target position, speed, and optionally acceleration and deceleration ramps. Other available commands include MC_Home and MC_MoveVelocity. It’s important to note that all commands comply with the PLCopen standard, which is an internationally recognized and widely used motion control standard. To execute a command, an Execute signal must be sent – this can be done through the network or via a programmed digital input.

Advantages of This Application

A major benefit of this application is complete servo drive control through the PLC. Changing the production profile involves adjusting control words in the PLC program. At any time, basic communication info between the PLC and the servo drive can be read. Control and status words can also be tailored to individual needs.

Free Software for Stöber Servo Drive Configuration

The free DS6 software and built-in PLCopen function blocks help reduce costs on PLC licenses. There’s no need to pay for motion functions since they’re included in the servo drives. Additional benefits include a user-friendly interface, access to help resources, and a Polish-language user manual. Moreover, Demero offers extensive support in selecting the right components, provides training on operation and programming, and creates sample applications.