Block Positioning in Servo Drives

Block positioning, servo drive positioning

Motor shaft position control

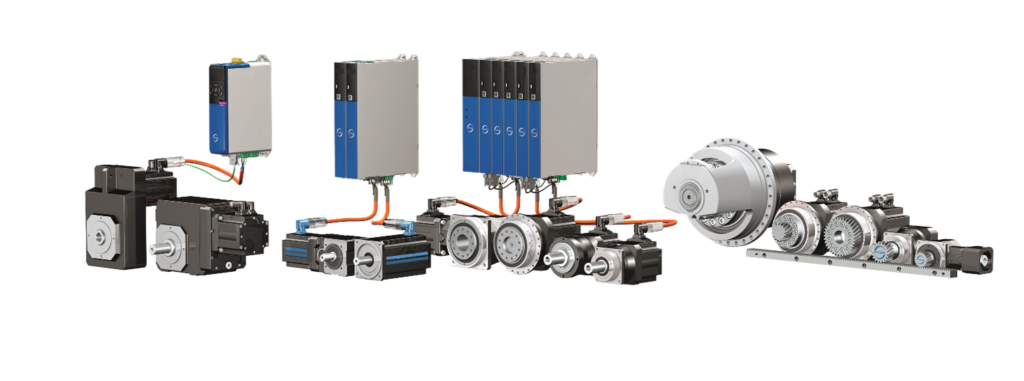

The new drive controller series from Stöber consists of SD6 servo drives, and dual-axis SC6 and SI6 drives.

The SD6 servo drive features a modular design, allowing the installation of optional communication and I/O cards. Additionally, industrial communication via Profinet, EtherCAT, and CAN is supported. The I/O card can be a basic IO6, the extended Xi6, or the Ri6 for resolver support. This servo drive allows control of a single connected motor. It is available in a basic safety version (STO) or an extended version with additional safety functions. The new series supports CIA402 applications as well as Stöber’s proprietary application: Drivebased.

The newer dual-axis drive controllers include the SI6 and SC6.

The SI6 requires a power supply (rectifier) – PS6, while the SC6 has an integrated power supply. Both types are compact. Built-in communication includes Profinet and EtherCAT. The communication protocol can be changed by updating the firmware manually. Each drive has 8 digital inputs and includes motor brake control. Various versions of STO safety functions are also available via terminals, Profisafe, or FSoE (Safety over EtherCAT). These newer types support Profidrive, CIA402, and Stöber’s Drivebased application.

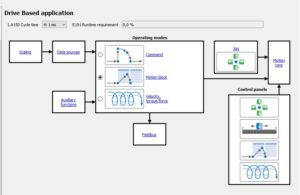

The Drivebased Application in Stöber Servo Drives

Let’s now take a closer look at Stöber’s Drivebased application, available in the aforementioned servo drives. Parameterization is done using the free DS6 – Drive Control Suite application. It includes three modes: command positioning, motion block positioning, and velocity/torque control. Below, we’ll focus on the motion block positioning application.

This application consists of pre-programmed blocks (cells), which can be defined by the user. Each block can be named and assigned a command from a list of available commands. These follow the international PLCopen standard. For example, you can select commands like MC_MoveAbsolute, MC_MoveVelocity, MC_Stop, MC_Home, and others. These commands are widely recognized, and the PLCopen standard is commonly used.

After selecting a command, corresponding parameters appear for configuration. Positioning commands require a target position and dynamics settings. Thanks to precision gearboxes, the positioning is highly repeatable and accurate. Velocity commands include a set speed and acceleration ramp. The MC_Home command executes a homing procedure. MC_Stop stops motion using a programmed stop ramp. You can program a sequence of blocks or define triggers that switch between blocks based on conditions—like time delays or digital signals. Comparators can also be created, where a met condition activates a block switch.

Advantages of Block Positioning

The main advantage of this application is the ability to quickly trigger movement by activating a block. A block can be initiated by a digital input or via industrial communication. There’s no need to transmit a large volume of data over the network, which improves performance. All that’s needed is a signal from the PLC or a block number and a start signal.

Free Application for Stöber Servo Drives

The free DS6 application and built-in PLCopen blocks/functions help reduce costs associated with motion licenses on the PLC. Since motion functions are built into the drives, you don’t need to pay extra. Additional benefits include a clear program interface, access to help, and a Polish-language manual for the servo drives. Moreover, Demero offers extensive support in selecting the right components, provides training in operation and programming, and can also create example applications.