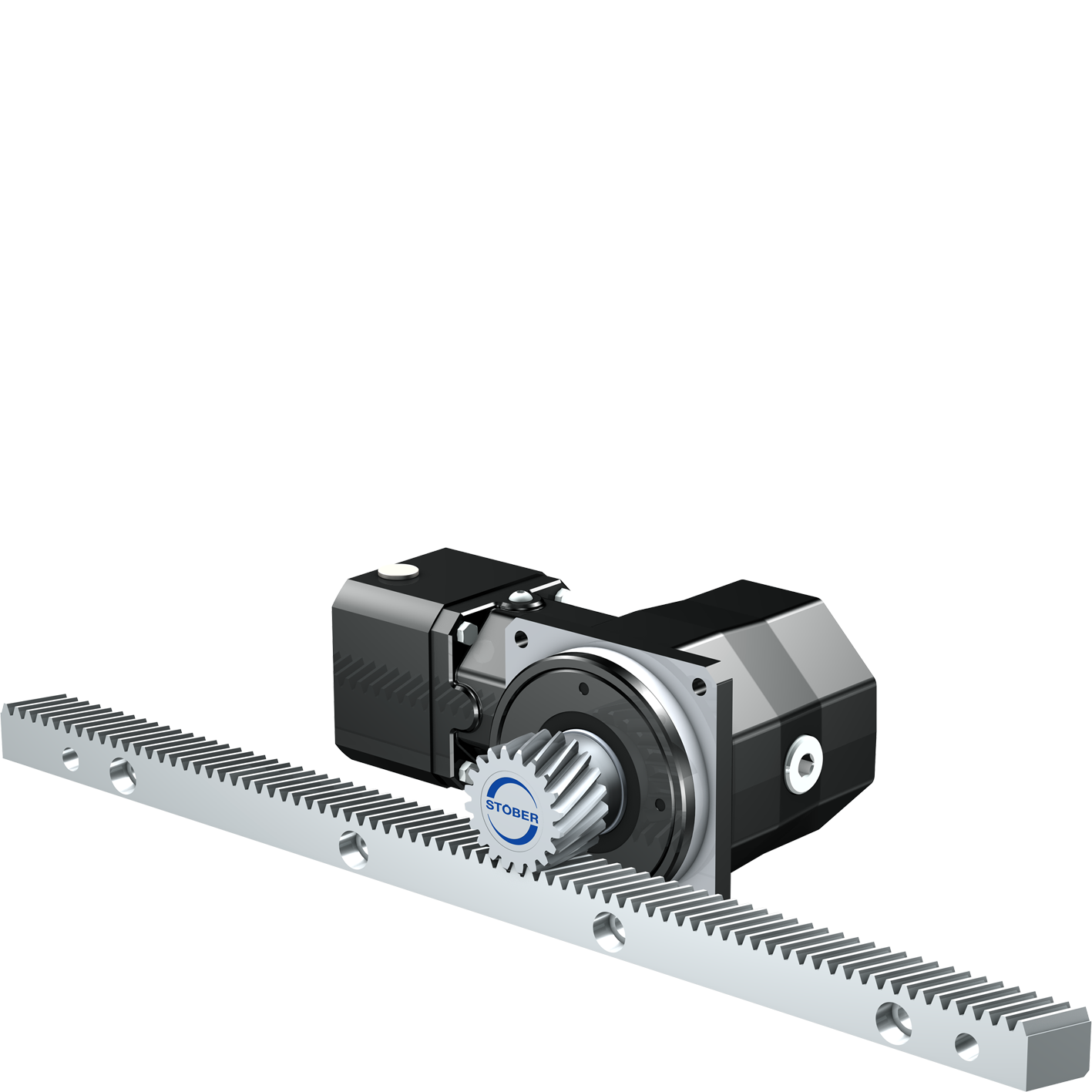

ZV-KS-ME angular rack and pinion drive

ZV modular rack and pinion with KS angular planetary gear and ME servo motor adapter. Gear modules 2 – 4. Number of teeth 18 – 25. Gear ratio range 6:1 – 200:1. Feeding forces 3.2 – 11 kN. Linear speeds 0.07 – 3.0 m/s. Linear play 37 – 44 µm. Dental quality class 6. Optionally with servo motor.

ANGULAR RACK AND PINION DRIVES ZV-KS-ME

Angular Servo Gearboxes with Plug-In Pinion

Modular ZV Gears:

- Gear quality class 6 according to DIN 3962.

- Helical gearing, surface-hardened and ground (left-hand 19° 31′ 42″).

- Backlash-free shaft-hub connection, shrink-fitted and keyway-secured.

- The corresponding rack must have a right-hand design (19° 31′ 42″), minimum quality class 8, material C45, induction-hardened.

- Two pinion mounting positions available:

- (E) Pinion at the end of the output shaft.

- (S) Pinion close to the gearbox, ensuring higher permissible feed forces.

- Pinion and rack ZV: Lubrication is the customer’s responsibility; high-quality synthetic oil-based greases (NLGI class 0) are recommended.

Modular ZS Racks:

- Precision helical gearing, quality class 6.

- Spiral teeth, hardened and ground.

- Module sizes ranging from 2 to 6.

- Double number of mounting holes every 62.5 mm.

- Maximum feed force from 12.6 to 83.1 kN.

- Two length groups: 500 mm and 1000 mm.

Properties of KS Planetary-Bevel Gearboxes:

- Precision – standard and reduced backlash.

- Fractional gear ratio – eliminates positioning errors.

- Quiet operation – helical gearing.

- Maintenance-free – no oil changes required.

- Pre-lubricated for the entire service life.

- Mounting position – to be specified upon ordering.

- Ambient temperature: 0°C to 40°C (other temperature ranges available on request).

- Filled with synthetic lubricant CLP HC ISO VG 150.

- Maximum allowable gearbox surface temperature ≤ 90°C.

- Protection class: IP65 (optional IP66).

- Bearing options: standard, reinforced axial or radial bearings.

- Output shaft sealing: standard NBR, optional FKM.

- For duty cycles > 60% and higher ambient temperatures, radial shaft sealing rings made of FKM are recommended at the output.

- Gearbox housing made of cast iron.

- Standard paint color: black RAL9005 (other colors available on request).

Optional KS Planetary-Bevel Gearbox Configurations:

- Mineral oil for applications in the food, beverage, and pharmaceutical industries.

- Oil expansion tank for vertical mounting position (EL5).

- Direct mounting of STOBER servo motors from the EZ/LM series without adapter or coupling.

Properties of Angular Adapters for KS Planetary-Bevel Gearboxes:

- Quick and easy mounting for any servo motor.

- One-piece, durable clamping coupling with expansion function.

- Lowest mass inertia moments for maximum dynamic performance.

- Balanced design for quiet, vibration-free operation, even at high speeds.

- Wide selection of motor shaft diameters and lengths.

- Precise alignment ensures perfect motor fit.

- Motor can be disassembled in any position.

- Optional double sealing for larger gearbox models.

- Optional direct mounting of EZ or LM servo motors without adapter and coupling.

- To reduce backlash, the motor shaft bearing must be designed without axial play.

EasyAdapt (ME/MEL):

- One-piece, durable clamping coupling with expansion function.

FlexiAdapt (MF):

- Durable, laser-welded bellows coupling with expansion function.

- Integrated thermal length compensation, accommodating the linear expansion of the motor shaft.

- Motor shaft isolated from axial forces.

Catalogs

443137_en_06_KAT_Zahnstangentriebe.pdf – Catalog of Stober gearboxes with rack and pinion drives in English

Formularz_przekladnie_STOBER_26082024.pdf – Inquiry form about Stober servo gears in Polish/German/English