Positioning in Stober servo drives

Drive-Based Application in DS6 Software for Servo Drive Programming

The sixth-generation Drive Control Suite (DS6) software by STÖBER offers convenient features for efficient configuration and quick project startup. It is suitable for synchronous operation of multi-axis systems or simple single-axis applications. The Drive-Based application integrated into DS6 provides universal motion control solutions based on single- and dual-axis SD6, SC6, and SI6 controllers, using position, speed, and torque/force control types. Standard commands related to these control types are divided into three modes: command-based control, motion block control, and torque/force or speed control. Additional features for monitoring process variables, such as positions or speeds, enhance observation convenience.

Steps to Start Configuring the Drive-Based Application

-

Create a New Project:

-

Select appropriate inverter sizes, installed options, and motor types.

-

Choose industrial communication, safety level, and application type to be parameterized.

-

Select and Configure Axes:

-

Define the axis type with the positioning range and apply axis scaling.

-

Choose a referencing/homing method: sensor-based homing, limit switch, preset torque value, or homing to the current position.

-

Parameterize Control Signals:

-

Choose digital/analog inputs, industrial communication, or both methods.

-

Test the preliminary configuration using built-in Jog panels for manual motion and motion commands for selected motion commands.

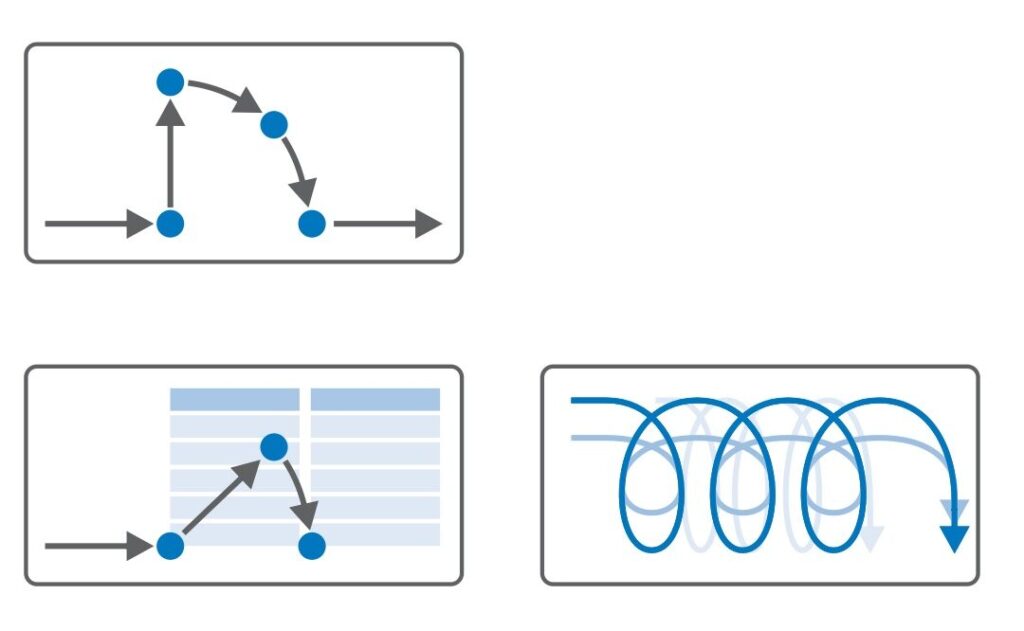

Operating Modes

The DS6 software supports various motion control modes in compliance with PLCopen standards, supplemented by unique motion commands. The best-suited mode depends on the application requirements:

-

Command-Based Control Mode: Use this mode for coordinated motion sequences managed by a controller.

-

Motion Block Control Mode: Suitable for cases where motion profiles are stored in the servo drive instead of a controller.

-

Speed or Torque/Force Control Mode: Ideal for simple applications with adjustable setpoints, such as pumps, fans, or conveyor belts.

Each mode provides unique wizards to parameterize motion variables specific to the mode.

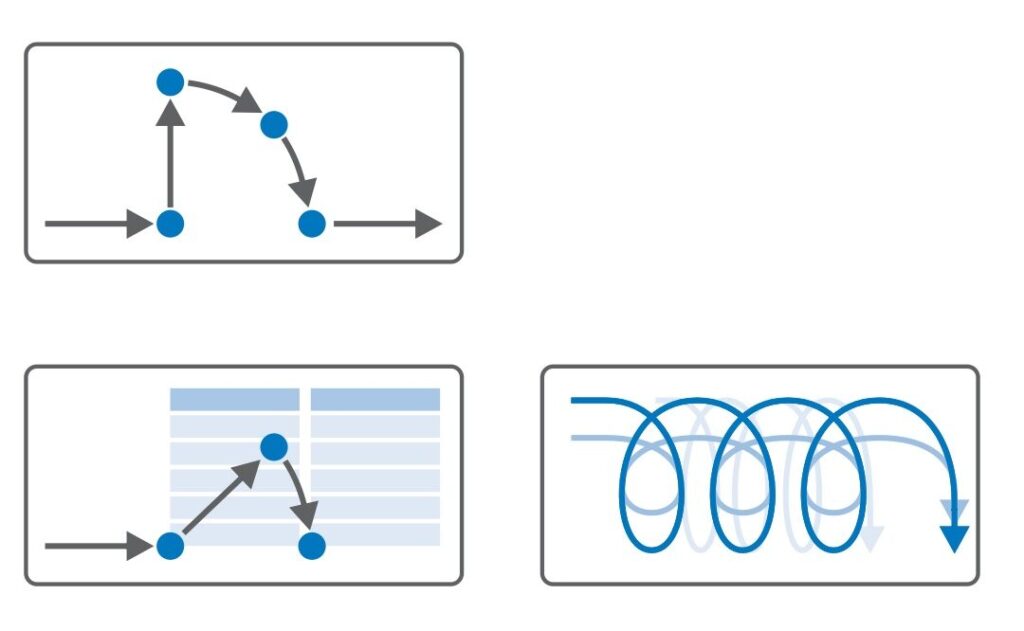

Speed or Torque/Force Control Mode

-

Individual motion commands and related setpoints are permanently stored in the drive controller.

-

Applicable for simple applications such as conveyor belts, pumps, or fans with set speed values, or screwdrivers, winders, or presses with torque/force values.

Steps for Speed/Torque Control Mode:

-

Enable the speed or torque/force control mode.

-

For speed mode:

-

Select the MC_MoveSpeed or MC_MoveVelocity command.

-

Parameterize the start signal for MC_MoveVelocity as needed.

-

Configure main and optional control signals if the setpoint is obtained externally.

-

Add fixed speed setpoints for switching between speeds.

-

Save acceleration, deceleration, and jerk values.

-

Optionally limit the maximum speed.

-

For torque/force mode:

-

Select the MC_TorqueControl command.

-

Parameterize related setpoints and limits.

Motion Block Control Mode

-

Motion profiles are stored in the servo drive as motion blocks.

-

Each block contains a PLCopen-compliant motion command and motion variables like speed, acceleration, deceleration, and jerk.

Steps for Motion Block Control Mode:

-

Activate motion block control mode.

-

Parameterize one or more motion blocks.

-

Test individual blocks using the motion block control panel.

-

Define sequences and triggers for linked blocks.

-

Parameterize signal sources for continuation, reset, or stop as needed.

Command-Based Control Mode

-

Motion profiles are sent from the controller to the servo drive as motion tasks.

-

The controller coordinates timing and selects motion tasks executed by the drive controller.

Steps for Command-Based Control Mode:

-

Enable command-based control mode.

-

Optionally limit torque/force in the mode.

-

Parameterize command-specific motion variables.

-

Define the start signal source.

-

Optionally define a continuation signal.

Documentation and Support

Detailed descriptions of all motion commands are available in the following manuals: