PLCopen Motion Commands in Stober Servo Drives

PLCopen is a leading global association of independent suppliers and products focused on topics related to industrial control programming. This standard is supported by numerous automation manufacturers. For many years, #Stober Antriebstechnik has also supported this standard. This allows automation engineers to adapt more easily to programming on new devices. It reduces commissioning and machine upgrade times, thereby lowering costs and increasing efficiency. An additional advantage is the ability to easily switch to new types of servo drives, even from other manufacturers, that support the described PLCopen standard. The more commands supported, the more possibilities a programmer has. Older types of servo drives may not support all commands, which is why it is worth checking what new types of servo drives offer. The PLCopen standard continues to be supported and developed. Below is a brief presentation of motion commands available in the latest SD6 and SC6/SI6 servo drives from #Stober, which comply with the #PLCopen standard.

PLCopen, Motion Commands, Motion Control

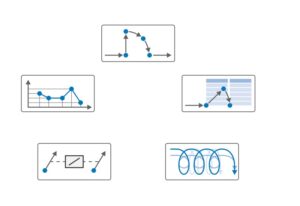

In the latest version of the Drive Control Suite 6.5-E software, the following motion commands can be executed:

Motion Command DoNothing

0: MC_DoNothing – Manufacturer-specific command for default settings.

Motion Command MoveAbsolute

1: MC_MoveAbsolute – The axis moves to an absolute position (referencing required).

Motion Command MoveRelative

2: MC_MoveRelative – The axis moves by a relative distance; the set position refers to the current position at the start of the command.

Motion Command MoveAdditive

3: MC_MoveAdditive – The axis moves by a relative distance; the position is set relative to the position set in the previous motion command.

Motion Command MoveVelocity

4: MC_MoveVelocity – The axis moves indefinitely at a set speed (speed control with position monitoring).

Motion Command Stop

5: MC_Stop – The axis stops; the next motion command can be executed after stopping.

Motion Command Home

6: MC_Home – The axis is referenced.

Motion Command CyclicSpeed

7: MC_CyclicSpeed – The axis moves indefinitely at a set speed (controller-driven motion).

Motion Command MoveSpeed

8: MC_MoveSpeed – The axis moves indefinitely at a set speed (speed control without position monitoring).

Motion Command TorqueControl

9: MC_TorqueControl – The axis moves indefinitely with a set torque/force.

Motion Command Halt

11: MC_Halt – The axis stops; the next motion command can be executed before stopping.

Motion Command GearIn

12: MC_GearIn – The axis moves synchronously with the master; clutch based on speed (electronic gearbox).

Motion Command GearOut

13: MC_GearOut – The axis ends the current synchronous motion and continues at the last synchronous speed (electronic gearbox).

Motion Command GearInPosition

14: MC_GearInPosition – The axis moves synchronously with the master; positional clutch (electronic gearbox).

Motion Command CamIn

15: MC_CamIn – The axis moves synchronously with the master; coupling based on speed (electronic cam disc).

Motion Command CamInAbsolute

16: MC_CamInAbsolute – The axis moves synchronously with the master; positional coupling (electronic cam disc).

Motion Command CamOut

17: MC_CamOut – The axis ends the current synchronous motion and continues at the last synchronous speed (electronic cam disc).

Motion Command CyclicSpeed

18: MC_CyclicSpeed – The axis moves indefinitely at a set speed (controller-driven motion).

Motion Command CyclicPosition

19: MC_CyclicPosition – The axis moves indefinitely to a set position (controller-driven motion).

In Stober SD6/SI6/SC6 servo drives, there are two programming options for positioning mode: command-based positioning or block-based positioning. Command-based positioning is intended for industrial communication with the PLC controller: Profinet or EtherCAT. Block-based positioning is intended for control using digital I/O of the servo drives. If speed or torque control is required, there is also an application for fast setpoint value input. The SD6 servo drive is designed for controlling a single motor, unlike the SC6/SI6, which can also be dual-axis. The modular construction of the SD6 allows for additional industrial communication cards: CAN, EtherCAT, Profinet, and one of three available I/O extension cards. The SD6 servo drive features an integrated brake controller and dual-channel safety (safety-STO). Easy diagnostics are possible thanks to a large, clear display. In contrast, the SC6/SI6 are compactly built, have built-in Profinet and EtherCAT communication, digital inputs, and brake control. They can control LeanMotor motors, which are servo motors without a physical encoder. Position and speed are calculated based on a mathematical model and current measurements in the inverter. All described servo drives can also control both servo and asynchronous motors.

The DS6 software, dedicated to programming SD6, SC6/SI6 servo drives from #Stober, is constantly developed and improved. For complex applications, technical consultation with Demero is always an option. Detailed motion commands are listed in the Motion Commands manual (V 6.5-H or higher) ID 443349.

443349-motion-commands-en.pdf – User Manual for PLCopen Motion Commands in Stober Servo Drives.