P-ME precision planetary gearboxes

Precision planetary gear unit P with ME adapter for servo motor. Total gear ratio range 3:1 – 100:1. Acceleration torque: 11 – 3,450 Nm. Nominal torque: 16 – 2,483 Nm. Continuous Input Speed: Up to 6,000 RPM. Cyclic Input Speed: Up to 8,000 RPM. Torsional Stiffness: Up to 407 Nm/arcmin. Backlash 1 – 8 arcmin. Efficiency 95 – 97 %. Protection class IP65 / IP66. Noise level ≤ 62 dB(A). Cast iron housing. Optionally with reduced backlash, with servo motor, safety brake, with rack and pinion, ATEX explosion-proof.

P-ME precision planetary gearboxes

Features of P-ME planetary gear units:

- Gear unit mounting via square flange.

- Precise – standard or reduced rotational clearance.

- No positioning errors – gear ratio in the form of a fraction.

- Maintenance-free – no oil change or maintenance required.

- Quiet – helical gears.

- Any operating position.

- High torsional stiffness.

- Low moments of inertia.

- Continuous operation without cooling.

- FKM seal at the input / NBR at the output.

- Stiff output bearing due to preload.

- Ambient temperature from 0 °C to 40 °C (other temperature ranges on request).

- Maximum gear housing temperature ≤ 90 °C.

- IP65 protection class.

- Synthetic gear oil type CLP HC ISO VG 150.

- One coat of primer in color RAL7001 or RA9005.

Optional versions of P-ME planetary gear units:

- Reduced rotational clearance.

- IP66 protection class.

- FKM VITON seal.

- Reinforced radial or axial output shaft bearing.

- Two or more paints and in any RAL colour.

- Special oils for the food industry.

- Explosion-proof design according to ATEX Directive 2014/34/EU.

- Directly mounted EZ/LM servo motor without adapter and clutch.

- Emergency brake in the MB servo motor adapter.

- With modular ZV gear wheel and toothed rack.

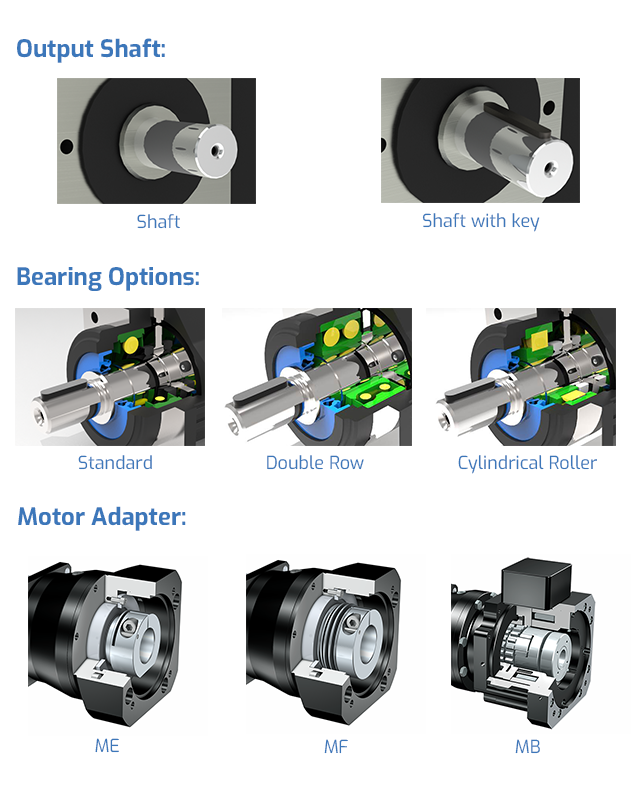

Output shaft shapes of P-ME planetary gear units:

- G – solid smooth shaft,

- P – solid shaft with key.

Features of the P-ME planetary gear adapters:

- Quick and easy attachment of any servo motor

- One-piece, robust clamping clutch with expansion function

- Low mass moments of inertia for highest operating dynamics

- Balanced for quiet, vibration-free operation, even at high speeds

- Wide selection of motor shaft diameters and lengths

- Flawless fit thanks to precise motor centring

- The motor can be removed in any position

- Double adapter seal for large gear models

- To reduce play, the motor shaft bearing must have an axially play-free design

EasyAdapt clutch (ME/MEL)

- One-piece, robust clamping clutch with expansion function

FlexiAdapt clutch (MF):

- Strong, laser-welded bellows clutch with expansion function

- With integrated thermal length compensation, compensates for linear expansion of the motor shaft

- Shaft motor separated from axial forces

- ServoStop servo motor adapter with safety brake (MB)

Examples of P-ME planetary gear applications:

- Gantry milling machines

- Horizontal machining centers

- Tripods

- Linear Cartesian robots

- Pick and place manipulators

- Laser cutting machines

- Sheet metal and pipe bending machines

- Feeders

- Tablet presses

Catalogues

443054_en_05_KAT_Servogetriebe.pdf – Stober gearboxes catalog.

Formularz_przekladnie_STOBER_26082024.pdf – Stober gearbox inquiry form.