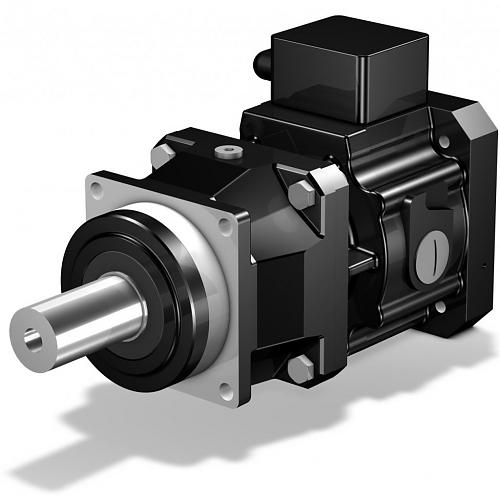

P-MB planetary gearbox with brake

Precision planetary gear unit P with safety brake in MB adapter for servo motor. Total gear ratio range 3:1 – 100:1. Torques 109 – 3,450 Nm. Brake rated torques 8 – 300 Nm. Backlash 1.0 – 4.0 arcmin. Efficiency 95 – 97 %. Safe braking in the event of a power failure. Optionally with servo motor, with modular rack and pinion, with reduced rotational backlash.

Properties of P Planetary Gearboxes:

- Various output shaft options:

- G – Solid smooth shaft

- P – Solid shaft with keyway

- Gearbox mounting via square flange.

- High precision – standard or reduced backlash.

- No positioning errors – fractional gear ratio.

- Maintenance-free – no oil changes or servicing required.

- Quiet operation – helical gear teeth.

- Flexible mounting position – can be installed in any orientation.

- High torsional stiffness.

- Low inertia moments.

- Continuous operation without additional cooling.

- Sealing: FKM at the input / NBR at the output (optional FKM VITON).

- Optional reinforced axial and radial bearings for the output shaft.

- Rigid output bearing due to preloaded tension.

- Ambient temperature: 0°C to 40°C (other ranges available on request).

- Maximum gearbox housing temperature: ≤ 90°C.

- Protection class: IP65 (optional IP66).

- Synthetic gearbox oil: CLP HC ISO VG 150.

- Standard coating: One primer layer in RAL7001 or RAL9005.

- Optional multiple coatings in any RAL color.

- Special food-grade oils available upon request.

- Optional explosion-proof design compliant with ATEX 2014/34/EU directive.

P planetary gear table

| Gear ratio ranges | Max. moments | Output shaft size | Rotational play | |

| Type | i | Nm | mm | arcmin |

| P231 / P221 / P211 | 4:1 – 10:1 | 25 | 12×22 | 6,0 |

| P232 / P222 / P212 | 16:1 – 100:1 | 25 | 12×22 | 8,0 |

| P331 / P321 / P311 | 3:1 – 10:1 | 80 | 16×28 | 2,0 – 4,0 |

| P332 / P322 / P312 | 12:1 – 100:1 | 75 | 16×28 | 3,0 – 5,0 |

| P431 / P421 / P411 | 3:1 – 10:1 | 145 | 22×36 | 2,0 – 4,0 |

| P432 / P422 / P412 | 12:1 – 100:1 | 139 | 22×36 | 3,0 – 5,0 |

| P531 / P521 / P511 | 4:1 – 10:1 | 385 | 32×58 | 1,0 – 3,0 |

| P532 / P522 / P512 | 12:1 – 100:1 | 364 | 32×58 | 2,0 – 4,0 |

| P731 / P721 / P711 | 3:1 – 10:1 | 840 | 40×82 | 1,0 – 3,0 |

| P732 / P722 / P712 | 12:1 – 100:1 | 805 | 40×82 | 2,0 – 4,0 |

| P831 / P821 / P811 | 3:1 – 10:1 | 2 000 | 55×82 | 1,0 – 3,0 |

| P832 / P822 / P812 | 12:1 – 100:1 | 2 000 | 55×82 | 2,0 – 4,0 |

| P931 / P921 | 4:1 – 10:1 | 3 450 | 75×105 | 3,0 |

| P932 / P922 | 16:1 – 100:1 | 3 450 | 75×105 | 4,0 |

Properties of MB Adapters with ServoSTOP Brake

- Adapter with integrated brake, combined with a planetary gearbox.

- Functions as a holding brake.

- Braking from full speed, e.g., in case of a voltage drop or emergency shutdown in hazardous situations.

- Can operate as a single brake or in combination with a motor brake for a redundant braking system.

- Electrically released spring-applied brake for dry operation.

- Equipped with a backlash-free plug-in coupling (jaw coupling), allowing easy motor disassembly with the braked shaft in any position.

- Electric release monitoring inside the terminal box using a contactless, wear-resistant proximity switch.

- Manual wear inspection by checking the air gap with a feeler gauge.

- Radial shaft sealing rings made of FKM with double sealing lips.

- Four oil drain holes to protect the brake from oil contamination in case of leakage.

- Differential-redundant system compliant with EN ISO 13849-1.

- Electrical connection: Standard in a junction box; optionally as a plug-in connector (not possible with release monitoring).

- In a de-energized state, braking is applied by spring force.

- The brake is released by a DC electromagnetic coil before the motor is activated.

- Standard motor plug connectors or terminal box/plug connector for the motor adapter are mounted in a 270° position.

- Combined with a motor brake, this solution provides dual braking with an exceptionally compact design.

Catalogs

443234_en_02_KAT_ServoStop.pdf – ServoSTOP catalog of Stober gears with brakes in the MB servo motor adapter in English

Formularz_przekladnie_STOBER_26082024.pdf – Inquiry form about Stober servo gears in Polish/German/English