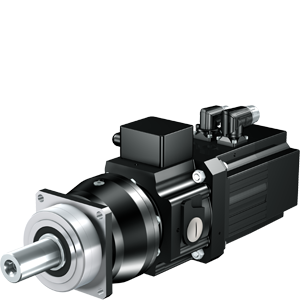

P-MB-EZ planetary servo drives with 2-brakes

P planetary gearboxes with MB adapter, EZ servo motor and two ServoSTP STOBER safety brakes. Gear ratio range 3:1 – 50:1. Static brake moments 8 – 100 Nm. Max. acceleration moments 84 – 3,450 Nm. Rotational backlash 1.0 – 4.0 arcmin. Efficiency 95 – 97%. Optional fan, single-cable servo motor, manual brake release, reduced rotational play, SD6 / SDS5000 servo drive.

Precision Planetary Gearboxes P:

- Various output shaft options:

- G – solid smooth shaft

- P – solid shaft with keyway

- Gearbox mounting via square flange.

- Precision options: Standard or reduced backlash.

- No positioning errors – gear ratio available in fractional form.

- Maintenance-free – no oil change or servicing required.

- Quiet operation – helical gear teeth.

- Flexible installation position.

- High torsional stiffness.

- Low inertia moments.

- Continuous operation without cooling.

- Sealing: FKM at the input / NBR at the output.

- Rigid output bearing due to preloaded tension.

- Ambient temperature: 0°C to 40°C (other temperature ranges available on request).

- Maximum housing temperature: ≤ 90°C.

- Protection class: IP65, optionally IP66.

- Synthetic gear oil: CLP HC ISO VG 150.

- Primer coating: One layer in RAL7001 or RAL9005.

Optional Configurations for Planetary Gearboxes P:

- Reduced backlash.

- FKM VITON shaft sealing rings.

- Reinforced axial and radial bearing of the output shaft.

- IP66 protection class.

- Modular output shaft gear.

- Mobil CIBUS 150/220 oil for the food industry, NSF H1 certified.

- With LM servo motor or ME/MEL adapter and coupling for market-available servo motors.

- With dual safety brake in the MB adapter and on the EZ servo motor.

- Explosion-proof design in compliance with ATEX Directive 2014/34/EU.

- Two-layer coating and custom RAL color upon request.

Servo Motor Adapter (MB) with ServoSTOP Brake

- The holding current brake is integrated into the motor adapter.

- Functions as a holding brake.

- Capable of braking from full speed, e.g., in case of a voltage drop or emergency shutdown in hazardous situations.

- Can operate as a single brake or in combination with a motor brake as a redundant braking system.

- Electrically activated for dry operation.

- Features a backlash-free plug-in coupling (jaw coupling) for easy motor removal with the shaft held in any position.

- Electric release monitoring in the terminal box via a non-contact, wear-resistant proximity switch.

- Manual wear inspection by checking the air gap with a feeler gauge.

- Radial shaft sealing rings made of FKM with two sealing lips.

- Four oil drain holes prevent brake contamination in case of an oil leak.

- Differential-redundant system in compliance with EN ISO 13849-1.

- Standard electrical connection via terminal box, optionally as a plug-in connector (not possible with release monitoring).

- In a de-energized state, braking is performed by spring force.

- Released by a DC electromagnetic coil before motor startup.

- Motor plug connectors or adapter terminal box/plug connector are mounted in the 270° position.

- When combined with a motor brake, it provides a dual-brake system with an exceptionally compact design.

EZ Servo Motors

- Permanent magnet synchronous electric motors.

- Rotating plug connectors with quick-lock mechanism.

- Operating temperature range: -15°C to +40°C.

- Standard protection class: IP56, optionally IP66.

- Thermal class: F (155°C).

- Electronic nameplate for quick servo motor parameter recognition.

- Rolling bearings with lifetime lubrication and non-contact sealing.

- Radial shaft sealing rings made of FKM VITON.

- Radial and axial runout tolerance according to IEC 60072-1.

- Permissible noise level values compliant with EN 60034-9.

- Not suitable for hazardous (explosive) environments.

- Certifications: CE, UKCA, optionally cURus.

- Integrated PTC thermistor, optionally with PT1000 temperature sensor.

- Standard color: Black (RAL9005), optionally any RAL color.

- Optional features:

- Backlash elimination for multi-turn absolute encoders.

- External fan for higher ambient temperatures, increased continuous power output, or 30% higher torque.

- 24V DC electromagnetic safety brake.

Encoders in EZ Servo Motors:

- Resolver

- Absolute encoder EnDAT 2.1/2.2 (inductive/optical, multi-turn/single-turn)

- Optional one-cable solution (OCS) with absolute encoder EnDAT 3.0 – EQI 1131, supporting cable lengths up to 100m

EZ Servo Motors Compatibility with Servo Drives:

- STÖBER: SDS5000, MDS5000, SI6 / SC6, SD6

- B&R: Acopos

- Beckhoff: AX5000

- KOLLMORGEN: AKD, S300, S400, S600

- SIEMENS: Sinamics S120

- Bosch Rexroth

- Allen-Bradley

Katalogi

443311_en_02_KAT_Synchron-Servogetriebemotoren_MBEZ.pdf – Catalog of STOBER servo motor reducers with double safety brake in English

serwomotoreduktory_STOBER_26082024.pdf – Inquiry form about Stober servo motors in Polish/English/German

DEMERO spółka jawna M.Mrugała, D.Nosiadek

ul. Graniczna 145

54 – 530 Wrocław, Polska

Telefon +48 713 882 300

E-mail: biuro@demero.pl