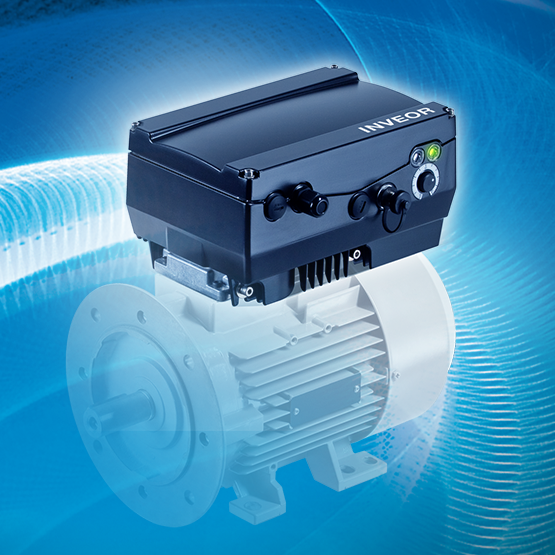

INVEOR M inverter

Inveor M vector inverter by Kostal, splash- and dust-proof, with IP65 protection class. Motion controller for electric synchronous and asynchronous motors with power range from 0.25 to 22.0 kW. Suitable for wall mounting or direct motor mounting. No electrical cabinet required. Equipped with a mobile Bluetooth app. Optional communication via Profinet, Profibus, EtherCAT, CANopen, Modbus, or Sercos.

INVEOR M KOSTAL Inverter

- Intelligent

- Robust

- Durable

Imagine a variable-frequency drive mounted on a motor controlling the air conditioning compressor of a city bus. A simple task for a drive controller. But now think about that bus running its route 24 hours a day, all year round — including acceleration, braking, and potholes. You quickly realize that even a simple task requires an intelligent solution, encapsulated in a robust and durable variable-frequency drive.

INVEOR M KOSTAL Frequency Converters

The INVEOR M inverter is a motion controller for electric motors, designed with a modular concept that can be optimally adapted to customer needs. They are available as three-phase and single-phase variable-frequency inverters in five sizes from 0.25 kW to 22 kW, making them extremely versatile. The solid aluminum housing provides flexibility, allowing the INVEOR M to easily meet the demands of mobile applications such as cooling or braking devices.

Thanks to its motor-mounted design, the INVEOR M does not require a control cabinet or additional power cables, reducing EMC emissions and purchase costs. At the same time, its neat and clean appearance provides an intelligent overview, applicable across all areas of use.

Features of INVEOR M KOSTAL Vector Inverters:

Robust aluminum housing:

Avoid costly failures and reliably control your speeds maintenance-free — even in mobile and heavy-duty applications.

Low maintenance costs and high durability:

Fanless design up to 7.5 kW and intelligent DC link concept with film capacitors reduce susceptibility to failure and ensure a long service life.

Circuit boards for various inverter applications:

Take advantage of its versatility and adapt the INVEOR M to your needs — with additional safety functions and fieldbus interfaces.

Adapter plates for all motor types:

Innovative adaptation concept with a wide range of standard and motor-specific adapter plates allows use with almost any motor available on the market.

INVERTERapp for INVEOR inverters:

Commissioning, parameterization, and monitoring — now all easily done wirelessly via Bluetooth using your smartphone or tablet.

Control Process of INVEOR M KOSTAL Inverters:

The motor-mounted INVEOR M inverter is available in five sizes covering a power range from 0.25 kW to 22 kW. This provides the right power for any application area — always with sufficient overload capacity.

Thanks to sensorless field-oriented control, the INVEOR M also achieves improved starting torque and higher efficiency. This enhances the quality of electric motor speed control, increasing your productivity. It also reduces costs, as there is no need for maintenance-intensive encoder feedback functions.

Operating Parameters of INVEOR M Inverters:

-

Overload capacity up to 150%:

Use up to 150% overload for a maximum of 60 seconds when needed, easily overcoming power peaks. -

Speed control range 1:20:

Control your three-phase motors precisely, thanks to an optimized speed setting range and high-quality control. -

Control of synchronous and asynchronous motors:

Take full control of the speed of all your asynchronous and synchronous motors — up to IE4 efficiency class. -

Power range 0.25 kW – 22 kW:

Choose the inverter with the appropriate power from five available sets — paying only for what you truly need.

INVEOR M KOSTAL Inverter Communication:

INVEOR M inverters offer a wide range of interfaces and communication options, allowing seamless integration into all your processes while still maintaining compatibility with existing internal fieldbus systems.

Communication Interfaces of INVEOR M Inverters:

-

CANopen

-

ProfiBUS

-

ProfiNET

-

Sercos III

-

EtherCAT

-

Modbus RTU

Optionally, you can take advantage of a variety of printed circuit boards for different applications. In addition to standard Modbus RTU, equip the INVEOR M inverter with the interfaces that suit your needs.

INVEOR M Inverter with Bluetooth:

Control your INVEOR M inverter via Bluetooth if desired — either permanently installed or as a plug-in solution.

Operation and Monitoring of the INVEOR M Inverter

The KOSTAL INVEOR M drive controller can be customized to suit all your operation preferences. Mobile control via an app is also possible, providing maximum flexibility.

Choose the operating functions that best suit your needs:

-

Potentiometer

-

Membrane keypad

-

Human-Machine Interface (HMI) on the cover or via cable

-

Wall-mounted touch panel

-

KOSTAL INVERTER mobile app

-

KOSTAL INVERTER PC software

Mounting the INVEOR M Inverter on a Motor

Instructions:

Datasheet_INVEOR-M_Kostal.pdf – INVEOR M KOSTAL vector inverter datashe

Manual INVEOR M drives controllers.pdf – User manual for INVEOR M vector inverters (English)

Manual INVEOR M alpha drives controller.pdf – User manual for INVEOR M Alpha vector inverters (English)

DEMERO spółka jawna M.Mrugała, D.Nosiadek

ul. Graniczna 145

54 – 530 Wrocław, Polska

Telefon +48 713 882 300